How Do You Create 3D Geometry?

[You should read the tutorials about the basic geometric

entities (points, lines, polylines, curves, combo curves, and surfaces) before

reading this tutorial. This tutorial talks about using those basic entities to

create complex 3D shapes.]

Pilot3D gives you many ways to create surfaces and piece them together

to get complex 3D shapes. Some ways are easier than others, so it helps to have

an overview of the different techniques. This tutorial will give you a feel for

the process and point you to more detailed tutorials.

Exact or General Shape

The first thing to determine is whether the 3D model you want to design

has exact dimensions that you want to match up. Many people want to recreate

(as closely as possible) some sort of 3D object. It might be a car or a

building. For this, you might want to start with a sketch that shows the basic

dimensions and positions.

To do these measurements, you need to know something about [X,Y,Z]

coordinates. You need to define your object relative to some sort of measuring

location or origin. You need to change measurements of length, width, and

height into [X,Y,Z] positions. For example, if you want to define a house, you

need to define a starting point (origin) for measuring everything, which might

be the southwest corner of the lot. This is the point you need to define all

[X,Y,Z] measurement points. Then you could say that the positive X-direction

goes to the east, the positive-Y direction goes north, and the positive-Z

direction goes straight up. All of the dimensions of the house could be changed

into [X,Y,Z] values measured from the corner of the lot.

A fast way to start in Pilot3D is to define point entities for each

critical point on the house; each house corner, each window and door corner,

each roof corner, even points that define the key points on the chimney. You

can use the Point-Add Point command and then right-click on the point to pop up

a dialog box to set the [X,Y,Z] value of that point. As you can see, this is

much more difficult than creating a 3D object that doesn’t have exact

measurements to match up.

Once you have all of the critical points defined, you can snap lines or

polylines between the points. This is done with the basic Curve-Add Polyline

command, but instead of left-clicking the definition of each point, you

position the cursor near one of the previously defined points and press the ‘p’

key on the keyboard. This tells the program to snap (use) the position of the

edit point that is closest to the cursor location.

Going from polylines and curves to surfaces

OK, but there has to be some method to all of this. The goal is to

create lines or edges that you can connect (skin/loft) with a surface. Think of

a simple rectangular side of a house with 4 points that define the corners. You

could snap a line between the top 2 points and snap a separate line between the

bottom 2 points. Then you can use the Create3D-Skin/Loft command to stretch a

surface between the two lines.

This is a common method for creating 3D objects with specific

measurements; define points, snap lines or curves between the points, and then

skin/loft surfaces between the lines or curves. [Some designers skip points and

go straight to lines and curves to speed up the process.] If the lines or curves

define the boundaries of the object, you will end up with a complete 3D NURB

model when you are done with the skinning/lofting process.

As you will see, converting lines, polylines, and curves to surfaces is

a common technique for creating NURB surfaces.

Here is a list of these commands, available under the Create 3D

pull-down menu.

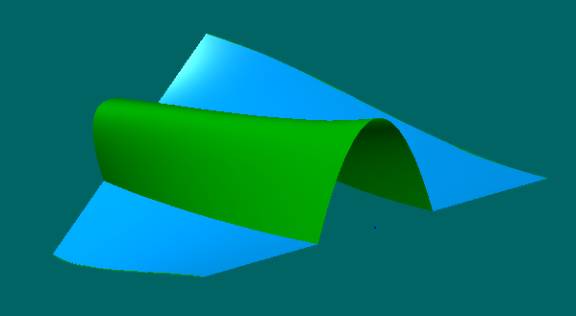

Create3D – Extrude Surface – Extrude Straight

This command takes a line, polyline, curve, or combo curve and creates a

surface by extending the curve straight (into the screen direction) based on

the view displayed. For example, you could take one of the standard 2D airfoil

shapes and create a full 3D airfoil by extending the 2D shape for 3 meters.

Note that for any of these extrude commands, when it is applied to a

polyline or combo curve, many surfaces could be created. For example, if you

extrude a 2D square, it becomes a 3D box made up of 4 separate surfaces. The

added bonus, which is VERY IMPORTANT for 3D modeling, is that these surfaces

are “bonded” or connected. This means that you can edit the extruded shape and

the surfaces will not separate. Very few (if any) other CAD programs offer this

capability. Surfaces can also be un-bonded or bonded edges can be changed to

smooth edges – combining two surfaces into one surface (or vice-versa), kind of

like the “knuckle” command for curves. See the tutorial on geometric

relationships for more details.

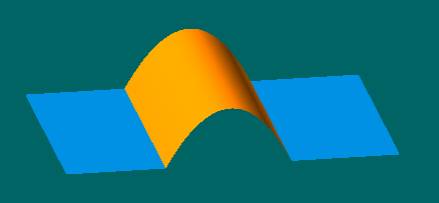

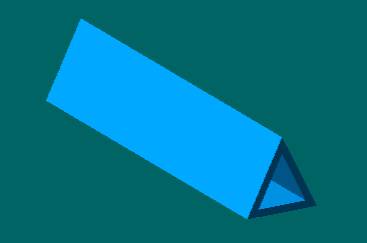

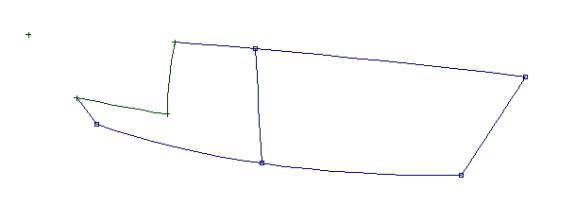

This picture shows a straight-extruded combo curve consisting of two

straight lines connected with a curve.

Pilot3D creates three NURB surfaces and bonds the common edges between

the flat and curved surfaces. This means that you can edit the surface edges

without having the surfaces split apart.

[Note: bonded edges have the added bonus of being exact, “watertight” connections

between surfaces. This is important when you need to transfer the surfaces to

solid modelers.]

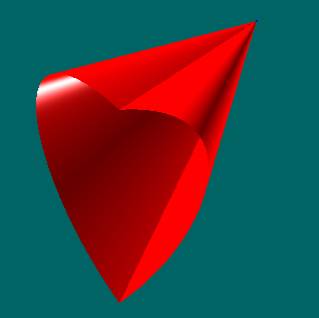

Create3D – Extrude Surface – Extrude to a Point

This command creates a 3D shape that starts as a 2D shape and disappears

down to a point – kind of like an arbitrary cone, except that the shape is

whatever you want.

This picture shows two surfaces created by extruding a heart-shaped

combo curve to a point. Combo curves

are very powerful when combined with the extrusion, shelling, and skinning commands.

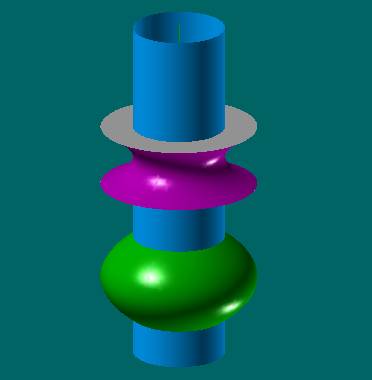

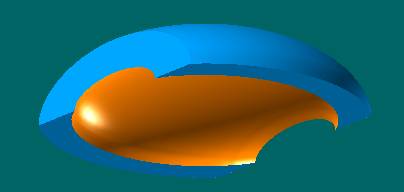

Create3D – Extrude Surface – Extrude Rotate

This command takes a 2D shape and rotates it about an axis (that you

define) to create a 3D shape. Think of a lathe pattern that is used to cut out

a circular object, like the leg of a table. Note that the rotation angle to use

does not have to be 360 degrees, a full circle.

This collection of surfaces was created in one step using the

Extrude-Rotate command on a single combo curve consisting of both straight and

curved sections. This shape was created in about a minute. The surfaces are

bonded together so that you can edit the shape without having the surfaces come

apart. Since they are separate surfaces, they can have their own colors.

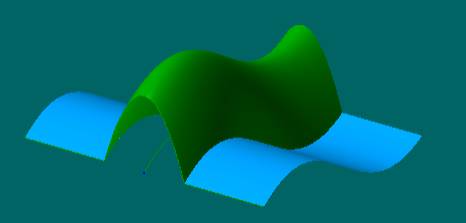

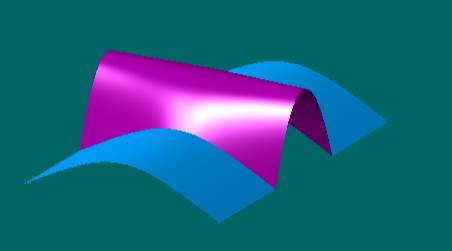

Create3D – Sweep Surface – Sweep Along 1 Curve

This command extrudes a 2D shape, but follows a curve (that you define),

rather than a straight line. This is much more powerful than a straight line

extrusion.

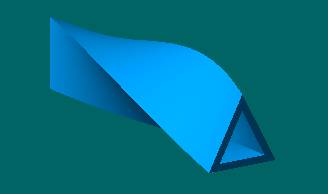

These surfaces were created by sweeping a combo curve along on curved

path. If you look closely in the center opening, you will see the start of the

sweep path. As with the other commands, these surfaces are bonded and can be

edited without having the surfaces separate.

Create3D – Sweep Surface – Sweep Along 2 Curves

This command allows you to create a 3D surface by moving a 2D

(cross-section) shape between 2 edge curves. This is more complicated, but

quite powerful.

This shows surfaces that were created by sweeping a combo curve along

two paths defined at the ends of the straight curve segments. Some programs

call this a two-rail sweep. Once again, the surfaces are bonded.

Create3D – Skin/Loft Surface

This is a very powerful command that creates a surface between two or

more lines, polylines, or combo curves. The fastest way to create 3D surfaces

is to use this command between two lines or curves. If you have a series of

cross-section curves of a more complicated surface, this command allows you to

fit a 3D NURB surface that matches (passes through) all of the cross-section

curves. If the “curves” are really polylines or combo curves, and if all of the

polylines or combo curves have the same number of sections, then this command

will fit multiple surfaces between the polylines.

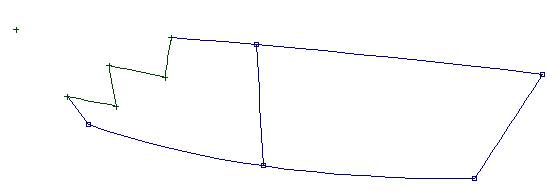

This command fits one or more surfaces to a set of cross-section curves.

In this case, the curves are combo curves and all of them have the same number

of curved and flat sections. The Skin/Loft command will create multiple (3 in

this case) surface that fit each section.

Pilot3D figures finds the three different sections of the curves and

uses those sections to create different surfaces. Three surfaces were created

in the example above and the surfaces were bonded to make further editing

easier.

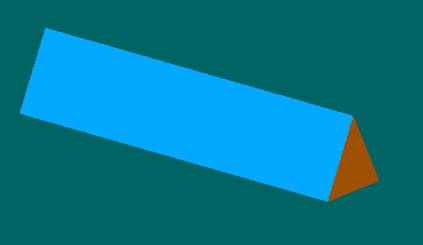

Direct 3D Solids

There are also commands that can give you (without starting with curves)

basic 3D shapes. They are listed in the Create3D pull-down menu and below. Each

of these shapes can be defined as hollow in the middle.

Triangle Solid – the triangle can change shape and twist angle from one

end to the other.

The triangle solid can be closed and bonded completely with NURB

surfaces. The triangle can be any different size on the front and back.

All solids can be defined with any thickness, like a pipe. This picture

shows a triangle with all surfaces (inside and out) defined and bonded

together. You can edit the shape without having the surfaces separate.

You can even put a twist into any of the 3D objects – still all closed

and bonded.

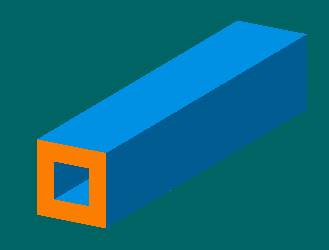

Box Solid – The rectangle can change shape and twist angle from one

end to the other.

Box solids have the same type of options as the triangle solids. You can

define twist and have the dimensions (width and height) of the two ends be

different.

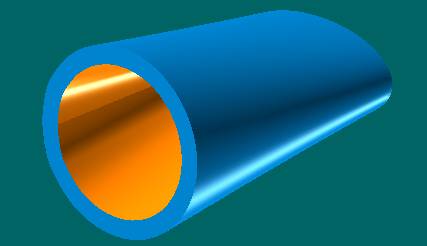

Cylinder/Cone Solid – The shape can change from a circle to an ellipse

and can be truncated or skewed.

This is a picture of a circle to ellipse cylinder/pipe that was created

with one command. The shape does not

have to be closed. You could define the shape to cover one-quarter of the

closed loop, with the open edges closed off with bonded surfaces.

Sphere/Ellipsoid Solid – This solid can be any angle, from a wedge to a

full, round solid.

This is half an ellipse of a specified thickness with its ends cut off

and capped with surfaces. All surfaces are bonded. This was done with one

command.

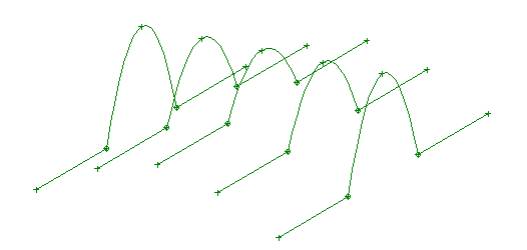

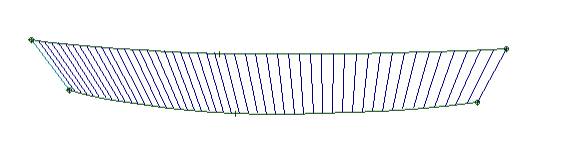

Ruling Line Surfaces

Sometimes, one wants to create surfaces that can be unwrapped from a 3D

shape to a 2D pattern. Pilot3D allows you to create dynamic 3D ruling lines

between any two curves. This is great for cloth patterns, like clothes,

awnings, tents, and kites. You can also use this for curved buildings and boats

made out of sheets, like plywood, aluminum, and steel. You can edit the curves

to get the shape you want and to check the developability of the surface. This

means that you can unwrap the shape without any worry of wrinkles or

creases. Pilot3D can plot the 2D

pattern full size or you can send the pattern to a CNC cutting machine. See the

Develop pull-down menu for the list of commands.

You can have the program calculate and draw ruling lines between any two

curves, as shown above. When you edit (move) any of the edit points, the

program dynamically recalculates and draws the ruling lines. The ruling lines

will be drawn using colors that define the amount of twist in the surface. If

the ruling lines are dark blue, then there is no twist and the surface can be

unwrapped with no kinks or strain. As the colors go from dark blue to green, to

yellow, and then to red, the amount of twist increases. This technique allows

you to dynamically get feedback on developability as you are editing the shape

of the curves. Once you get the ruling

lines just right (like above), then you can fit a NURB surface through the

ruling lines and then unwrap the 3D shape into its 2D pattern, as shown below.

No other program has this dynamic ruling line

calculation capability.

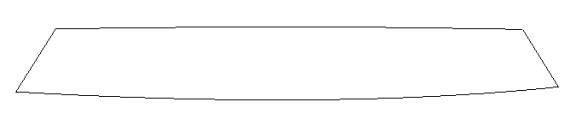

The final 2D pattern can be plotted full size or you can send the

numbers to a DXF file to use with any CNC cutting machine.

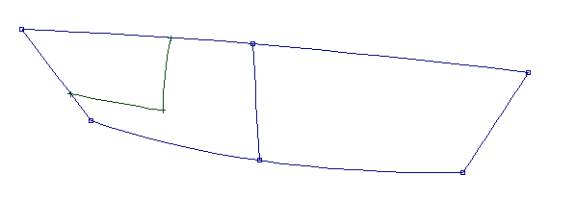

Trimming Curves

Sometimes, it might be useful to define sections of a surface to cut off

or cut out. Pilot3D allows you to intersect surfaces or define curves on

surfaces that can be used to trim surfaces. This is a more complicated subject,

so you should see those tutorials (and manual) for details.

This picture shows a simple NURB surface (with edit points on the

surfaces) and a polyline that is attached to the surface. You can attach

polylines or curves to a surface with the Curve-Add Polyline to Surf and the

Curve-Add Curve to Surf commands. The polyline or curve will stay on the

surface even if you edit just like a regular polyline or curve.

Use the Surf-Trim Curve command to pick the trim curve on the surface

and then pick the part of the surface you wish to trim off. Pilot3D also allows you to edit the shape of

the trim curve after you have trimmed the surface. Most CAD programs require

you to untrim the surface, edit the shape of the curve, and then retrim the

surface.

This shows the same surface after the trim curve has been edited. Again,

this is done without untrimming the surface.

Attaching curves to surfaces to use as trim curves can save a lot of

time with the editing process. In many cases, you can create trimmed shapes

that are difficult or impossible to do with intersecting or extruded surfaces.